-

- Energy storage hydraulic control system with reliable energy monitoring

- Energy storage high-flow hydraulic forming system

- High-precision digital servo synchronous actuation system

- Energy storage high-flow electro-hydraulic servo test system

- Energy storage, large flow compensation and balance hydraulic control system

- High-frequency fatigue testing system

-

-

- Product

-

Solution

-

Energy storage hydraulic control system with reliable energy monitoring

- Energy storage high-flow power source start-up system

- Energy-saving electro-hydraulic control system

- Hydro-controlled system of electric furnace energy storage device power source

- Emergency control high-pressure accumulator power source for valves

- Governor energy storage power source electro-hydraulic control system

-

Energy storage high-flow hydraulic forming system

-

High-precision digital servo synchronous actuation system

-

Energy storage high-flow electro-hydraulic servo test system

-

Energy storage, large flow compensation and balance hydraulic control system

- High-frequency fatigue testing system

-

Energy storage hydraulic control system with reliable energy monitoring

- Service

- Calculation

-

-

-

Energy storage hydraulic control system with reliable energy monitoring

-

Energy storage high-flow electro-hydraulic servo test system

-

Energy storage, large flow compensation and balance hydraulic control system

-

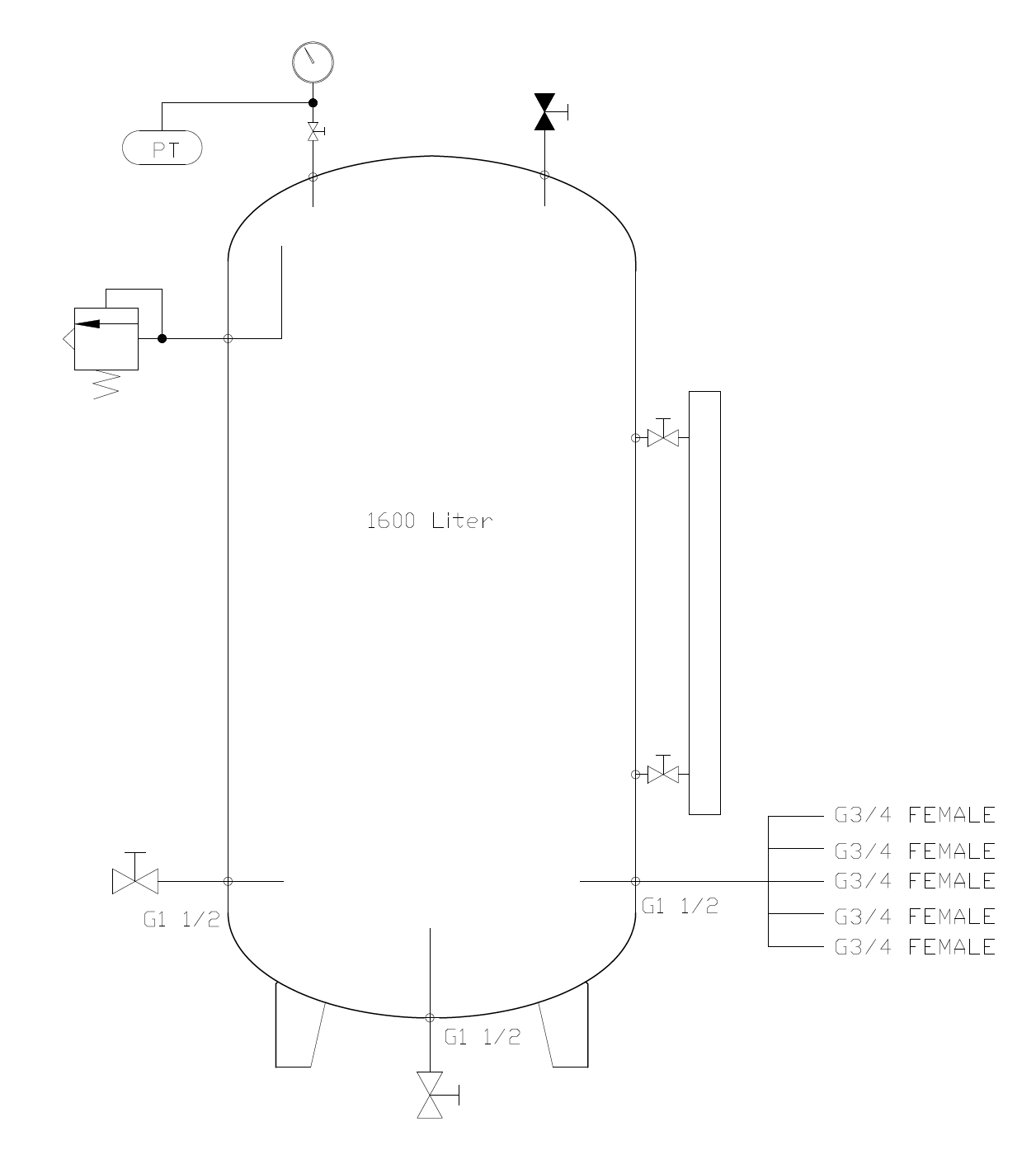

Oil-gas mixing tank with level monitoring

In low and medium pressure applications, oil-gas mixing tanks are used to control electro-hydraulic servo systems. The medium used is water and air, and the air is pressurized by an air compressor system. To ensure the reliable control of the oil-gas mixing tank, correct volume matching calculations and installation of a liquid level monitoring system are required.

Category:

Product Series

Standard accumulator

Oil and gas mixing tank

Oil-gas mixing tank with level monitoring

Keyword:

Standard accumulator

Product Attachment:

- Product Description

-

Oil-gas mixing tanks are an energy source frequently used in early electro-hydraulic control systems for medium and low-pressure applications. Advantages include lower operating pressure; however, disadvantages include higher maintenance requirements, significant noise, larger installation volume, and difficulty in meeting modern industry's maintenance-free operational requirements. Core control requirements include: (1) Internal anti-corrosion treatment (2) Reliable level control system (3) Accurate volume matching calculation

Seville Oil-Gas Mixing Tank Operating Parameters:

- Common Medium: Water (40%) and Air (60%)

- Maximum Operating Pressure: 100 bar

- Control System: On-site level display and pressure sampling, automatic replenishment and overload protection

- Inner Surface: Qualified inner wall treatment, anti-corrosion treatment

- Equipped with gas safety valve and overflow drain valve

Previous Page:

Next Page:

Which application field are you looking for solutions in?

High-frequency fatigue testing system for alternating stress

This product is a new generation of intelligent wireless sensor detectors upgraded and developed by our company. It is powered by active power supply and uses LoRa for local area networking. The effective transmission distance is far and the reliability is high. At the same time, it can be used for distributed networking layout environmental gas monitoring according to different environmental conditions, greatly reducing users' construction costs and complex data wiring. Through the edge gateway, data is uploaded to the cloud or intranet security control center via 4G, RJ45, and RS485 bus...

Energy storage high-flow rate ejection hydraulic control test system

This product is a new generation of intelligent wireless sensor detectors upgraded and developed by our company. It is powered by active power supply and uses LoRa for local area networking. The effective transmission distance is far and the reliability is high. At the same time, it can be used for distributed networking layout environmental gas monitoring according to different environmental conditions, greatly reducing users' construction costs and complex data wiring. Through the edge gateway, data is uploaded to the cloud or intranet security control center via 4G, RJ45, and RS485 bus...

Energy storage high-flow pulse collision test system

This product is a new generation of intelligent wireless sensor detectors upgraded and developed by our company. It is powered by active power supply and uses LoRa for local area networking. The effective transmission distance is far and the reliability is high. At the same time, it can be used for distributed networking layout environmental gas monitoring according to different environmental conditions, greatly reducing users' construction costs and complex data wiring. Through the edge gateway, data is uploaded to the cloud or intranet security control center via 4G, RJ45, and RS485 bus...

Constant flow energy storage power source test system

This product is a new generation of intelligent wireless sensor detectors upgraded and developed by our company. It is powered by active power supply and uses LoRa for local area networking. The effective transmission distance is far and the reliability is high. At the same time, it can be used for distributed networking layout environmental gas monitoring according to different environmental conditions, greatly reducing users' construction costs and complex data wiring. Through the edge gateway, data is uploaded to the cloud or intranet security control center via 4G, RJ45, and RS485 bus...

Our company's new products

High-parameter piston accumulator

Lightweight piston accumulator

Piston displacement energy monitoring system

Inquire Now

If you have any questions during the use of our products and services, please feel free to leave a message. We value your feedback and opinions.

Products of Different Specifications

Products

Application Fields

Application

Partners

Partner

Exporting Countries and Regions

Exported Countries

-

-

-

Energy storage hydraulic control system with reliable energy monitoring

-

Energy storage high-flow electro-hydraulic servo test system

-

Energy storage, large flow compensation and balance hydraulic control system

-

Schwerll Fluid Control (Beijing) Co., Ltd.

Address: Building 39B, Floor 1, No. 16, Huanke Zhong Road, Tongzhou Park, Zhongguancun Science and Technology Park, Tongzhou District, Beijing

Welcome to access our company through the following methods

Copyright © 2024 Schwell Energy Storage Technology (Beijing) Co., Ltd.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.